Putting FHDRM’s MIL-SPEC Design to the Test in a Third-Party Laboratory

Earlier this month, we announced an ongoing series where we would take a deeper look at some of DSE’s signatures products, exploring real world use cases and going behind their unique features and qualifications. We began June by focusing on the Full High Definition Rugged Monitor (FHDRM), a rugged screen designed with the needs of the aerospace and defense industries in mind.

Our previous post explored the product specifications, including its 1080p display, programmable bezel soft keys and ultra-thin form factor—find the complete article here in our knowledge center.

While those features are key in optimizing operations and providing powerful performance, what truly sets the FHDRM apart is its adherence to the rigorous requirements found in MIL-STD-810, 461, 704, and 1275 and in DO-160.

MIL-SPEC Design Put to the Test

Earlier this year, DSE’s FHDRM 10” display was selected for an Intelligence, Surveillance and Reconnaissance (ISR) application by a global-leading systems integrator specializing in the aerospace and defense industries. Before fielding the FHDRM in mid-2020 on a multi-use fixed wing aircraft program, DSE was contracted to validate the FHDRM’s performance through a third-party laboratory.

These third-party tests, in addition to the routine validation measures in place at the DSE facility, are a regular component of how we ensure product reliability and operational performance under the extreme conditions our products experience.

The laboratory tests conducted earlier this year focused on six testing conditions that challenged the FHDRM’s adherence to DO-160 criterion. Continue reading to learn more about how the FHDRM performed when put to the test.

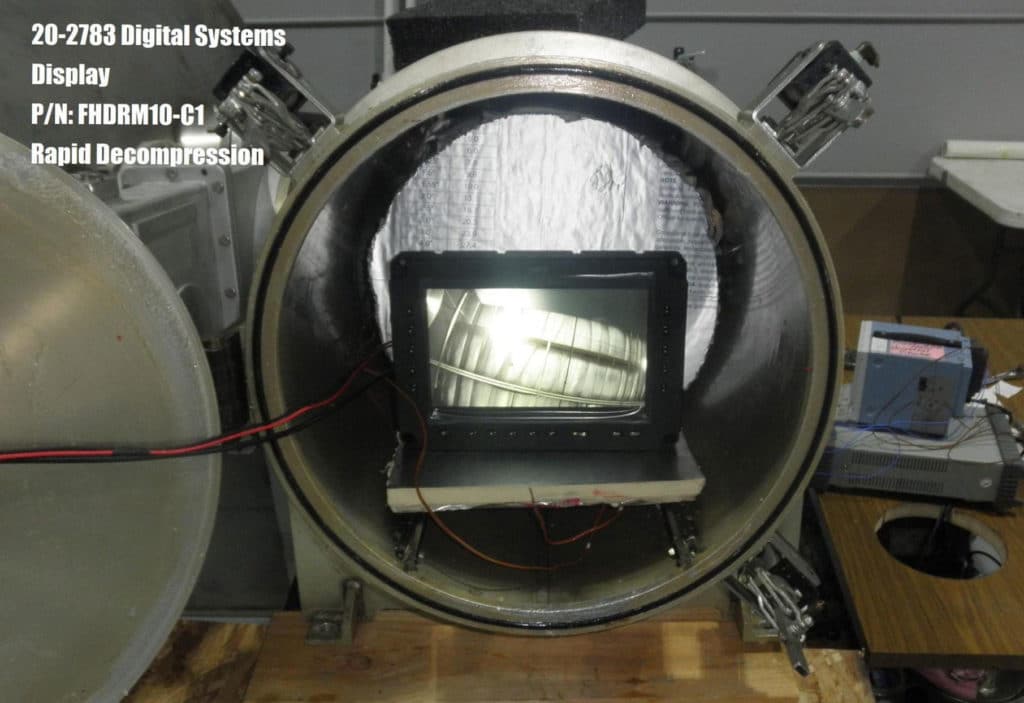

Rapid Decompression | DO-160G Section 4.6.2. 8,000ft to 25,000ft in 15 seconds

During a loss of pressure event, it’s essential to maintain product integrity. Poor construction during rapid decompression could result in product failure and possible human factor risks.

With the FHDRM unit in operation and installed in the chamber, absolute pressure was adjusted to an equivalent altitude of 8,000 ft (2,400 m) MSL. Once the temperature had stabilized, the absolute pressure was then reduced to 25,000 ft (7,600 m) within 15 seconds. Following the procedure, the FHDRM maintained the reduced pressure for a minimum of 10 minutes before being returned to ambient conditions. A visual inspection was then conducted for signs of product failure and the FHDRM was cleared, with zero defects or damage noted.

Altitude | DO-160G, Section 4.6.1 – 15,000ft

To test the FHDRM’s ability to function at a maximum operating altitude, the unit was returned to the chamber from the previous testing procedure with power applied. With the chamber sealed, the pressure was brought to 429 Torr (15,000 ft) and stabilized. These conditions were maintained for a minimum of 120 minutes before returning to ambient pressure.

With the test concluded, the FHDRM was visually inspected for signs of damage or failure, with no defects detected.

Operational Shock and Crash Safety | DO-160G, Sections 7.2 and 7.3

The first test in this category of procedures, operational shock, focuses on the effect of mechanical shock on product operation. Once the FHDRM was operating and secured in a standard mounting configuration, it was then placed onto an electrodynamic shaker. Three shocks were applied each of the six axes, for a total of 18 shocks. Each shock impulse had a terminal sawtooth wave shape with an acceleration peak value of 6gs and a duration of 11 milliseconds.

The next category, Crash Safety, encompasses two testing procedures, impulse and sustained. As in the operational shock procedure, the FHDRM was placed on an electrodynamic shaker. It was then exposed to shock impulses with a terminal sawtooth wave shape and an amplitude of 20gs and a duration of 11 milliseconds. With one shock administered in each direction, the FHDRM sustained a total of 6 shocks.

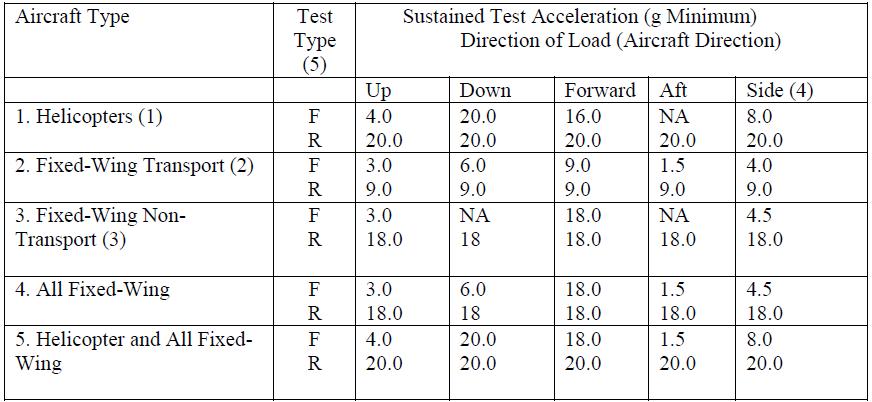

Finally, following the sustained Crash Safety testing procedures, the FHDRM was installed into a constant acceleration centrifuge. Distances from the center of the rotary arm to the nearest edge of the unit were then measured to calculate the RPM necessary to obtain the g levels in the table below. The FHDRM then was held for three seconds at the centrifuge’s full speed.

After undergoing each procedure, the FHDRM was inspected for damage, failure, or loose parts. No defects were noted and the FHDRM was cleared for the next test.

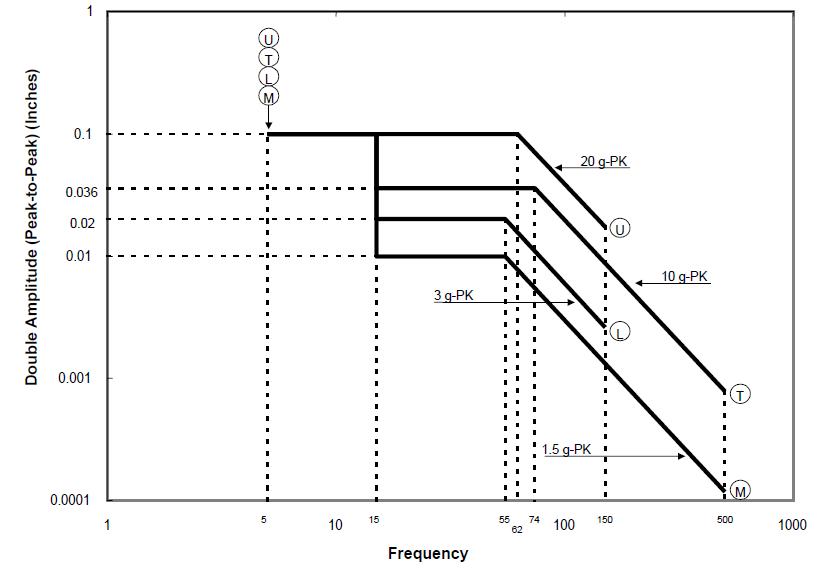

Vibration | DO-160G, Section 8, Curve L

Vibration tests are conducted dependent upon aircraft type to ensure that equipment remains operational during all vibration scenarios. Vibration testing was performed in conjunction with the previous operational shock test on an electrodynamic shaker. With the FHDRM in a standard mounting configuration and powered on, a triaxial response accelerometer was placed on the unit to track any resonances or changes during the vibration. The FHDRM was then exposed to the sine sweep profile below:

During the testing procedure, the FHDRM was closely monitored for changes in the screen quality and brightness and the response accelerometer was monitored to identify any resonances. This procedure was then repeated for the remaining two test axes.

With no defects noted, the FHDRM met the vibration testing standard.

Overpressure | DO-160G, Section 4.6.3 – 170kPa

Overpressure testing can be found in Section 4 of the DO-160G Test Procedure instructions. This procedure began with placing the FHDRM in a positive pressure chamber in its unpowered configuration. With the chamber sealed, the pressure was increased to 170kPa and maintained for ten minutes. Following the ten-minute period, the pressure was returned to ambient conditions and the FHDRM was removed for inspection.

Again, the FHDRM moved onto the next testing procedure, with zero defects or damage occurring.

Temperature | DO-160G, Section 4.5

Temperature tests refer to the ability of equipment to maintain operational performance during the extreme low and high temperatures that may be experienced in the field. The FHDRM was tested in four temperature ranges:

- Ground Survival and Short-Time Operating Low Temperature Test, Induced Cold: -55°C (-67°F) ) and -40°C (-40°F)

- Operating Low Temperature Test, Induced Cold: -15°C (5°F)

- Ground Survival and Short-Time Operating High Temperature Test, Induced Heat: 85°C (185°F) and 70°C (158°F)

- Operating High Temperature Test, Induced Heat: 55°C (131°F)

The high and low profile tests are each 8.25 hours in length and begin with the FHDRM being placed in a temperature chamber with power and video connected. Once the chamber is calibrated to the correct temperature, ground survival and short-time tests require a stabilizing period before the unit is left to soak, three hours in the case of ground survival and 30 minutes for short-time. During the operating high and low temperature tests, a stabilizing period is not required, but the unit soaks for two hours before returning to room temperature and undergoing further inspection.

The FHDRM was closely monitored throughout the testing procedure and the unit itself was inspected visually and operationally at the conclusion of each profile test. After the 16.5 hours of total temperature tests, the FHDRM received another pass, exhibiting full function in every extreme temperature it was exposed to.

In all of the six testing categories, the FHDRM lived up to its MIL-SPEC design, meeting each benchmark as laid out in the DO-160G Test Procedures as conducted. These tests were an essential validation method for DSE’s partner, and with the FHDRM meeting standards, the aircraft program is moving forward with fielding later this year.

A History of Rugged Performance

The laboratory results from earlier this year are hardly the first time the FHDRM has proved its performance under extreme conditions. Within the last year, the FHDRM 15” has undergone a series of altitude procedures to test its adherence to MIL-STD 810. These methods tested the larger FHDRM unit at a variety of chamber pressures, ranging from 8,000 ft (2,400m) to 40,000ft (12,200m) for up to one hour. As in the previous laboratory tests, the FHDRM proved its rugged durability, with no defects or damage noted.

At DSE, we understand the need for electronics to work every time. It’s not just key to maintaining product performance, in many cases it can make the difference in mission success. We put our products through rigorous testing, both internally and through third-party laboratories, to ensure they are ready for our clients’ extreme environments. From the northern reaches of the Arctic Circle to tropical jungles and the deserts of the Middle East, our partners can rest assured that their DSE electronics are built to last.

If you would like to learn more about environmental testing experience, with the FHDRM or any of DSE’s rugged electronics, we invite you to contact us with your comments and questions at sales@digitalsys.com.