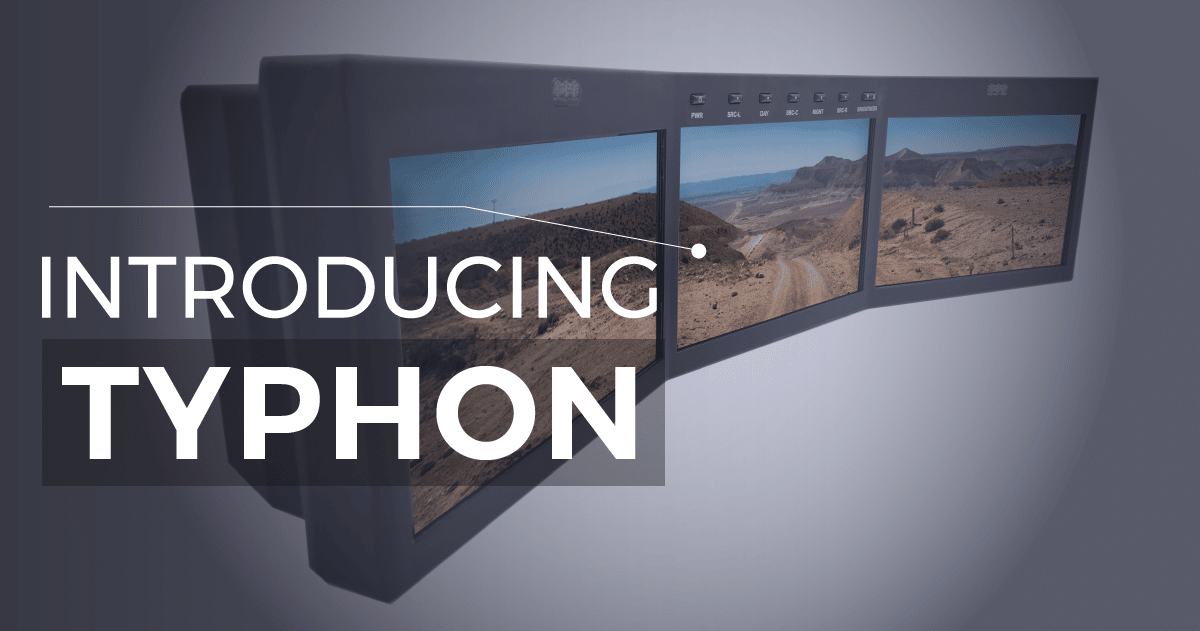

DSE releases powerful, next generation triple panel SDI display system for military vehicles

Introducing the Typhon Rugged Display

Scottsdale Ariz., (October 25, 2022) Digital Systems Engineering (DSE) today announced the release of the Typhon rugged display, a next-generation multi-screen system. Designed with the modern military fleet in mind, Typhon is engineered to withstand the most demanding environments while delivering unmatched, high-definition performance and reliability on the battlefield.

With advancements across the electronics industry, the demand among defense customers for cutting-edge technology continues to rise. The Typhon is among the next-generation solutions built to meet complex mission needs. Typhon’s three self-contained 10.1” LCDs screens deliver WUXGA resolution (1920 x 1200), giving vehicle operators a comprehensive view of their surroundings. Video is managed via six unique SDI and three RS-170 inputs, which allows for integration with legacy and advanced digital sensors. Typhon also features powerful communications capabilities, with onboard CANBus that permits remote control, video source selection, built-in-tests, day/night modes and user-controlled preferences.

“DSE is proud to add the Typhon to our family of rugged military displays,” said Ross Hudman, DSE’s Vice President of Sales and Marketing. “Typhon’s multi-screen design is a unique addition to our product catalog, but one that leverages decades of experience engineering and manufacturing rugged solutions. We are thrilled to know that next-generation solutions like the Typhon are working to enhance situational awareness, and to provide drivers with the information they need to ensure mission success and safety.”

Typhon is expected to be first integrated in a drivers’ station on an armored vehicle this coming year.

A full product data sheet and technical drawings can be requested by visiting: https://www.digitalsys.com/typhon/ or by contacting info@digitalsys.com.

About Digital Systems Engineering (DSE)

Founded in 1995, Digital Systems Engineering, Inc. (DSE) is a leading U.S. manufacturer and supplier of rugged military displays and industrial grade computers. DSE’s expert team of electrical, mechanical and software engineers provide customized design and manufacturing services to military forces, prime contractors and commercial sectors worldwide. DSE is an ISO9001/AS9100 registered company and qualifies as a US-owned, small business.

Learn more by visiting DSE at: https://www.digitalsys.com

What is SWaP-C?

What is SWaP-C?

In the world of aerospace and defense electronics, innovation is key to bringing to market new products that are optimized for today’s modern military. Today’s advanced vehicles and aircraft require equally modern solutions for improving efficiency and performance on the battlefield.

One acronym that has become synonymous with this movement to improved efficiency and evaluating solutions is SWaP-C, referring to the size, weight, power and cost of a product.

Size

Military electronics optimized for size often feature a smaller footprint while continuing to deliver the necessary capabilities. As a design-build manufacturer, DSE often develops products based on a customer’s unique specifications. Our engineering team works within space constraints to ensure that all internal components are designed with size in mind.

The VH4 video hub is just one example of a size optimization. With its miniature footprint of 6” x 6” x 1.13”, it packs powerful HD video processing and distribution in a small package.

Weight

It’s no surprise that reducing the overall weight of a vehicle or aircraft by optimizing its internal components will have a positive impact on its performance. Electronics manufacturers leverage new materials and design processes to make products lighter. DSE typically uses milled aluminum for enclosures, which are inherently rigid but also give endless flexibility in design possibilities, act as a heat sink for dissipation of heat, and ultimately a customizable form factor for weight reductions. This approach often results in products coming in at nearly 50% of the weight limit outlined in client program specifications.

Power

When it comes to power, requirements often specify that products perform the necessary tasks while drawing minimum current. Operating with reduced power consumption is achieved through knowledgeable circuit design, component selection, and total system level efficiency. These measures not only reduce total power draw but also reduce internal heat which increases the product’s expected lifespan. DSE’s engineering team leverage decades of experience building custom solutions to exceed customer specifications.

Cost

A new addition to the SWaP acronym, cost, is another factor to consider when evaluating a product. Optimizing for cost usually relies on the electronics provider standardizing common parts and driving down direct manufacturing costs, which can then allow savings to be passed to the customer. DSE applies this strategy, but also leverages its extensive library of subassemblies to reduce development costs.

There are many factors to consider when choosing a product or a manufacturing partner, SWaP-C among them. To learn more about DSE’s 27+ years of experience engineering rugged electronics for the aerospace and defense industry, contact our team at info@digitalsys.com.