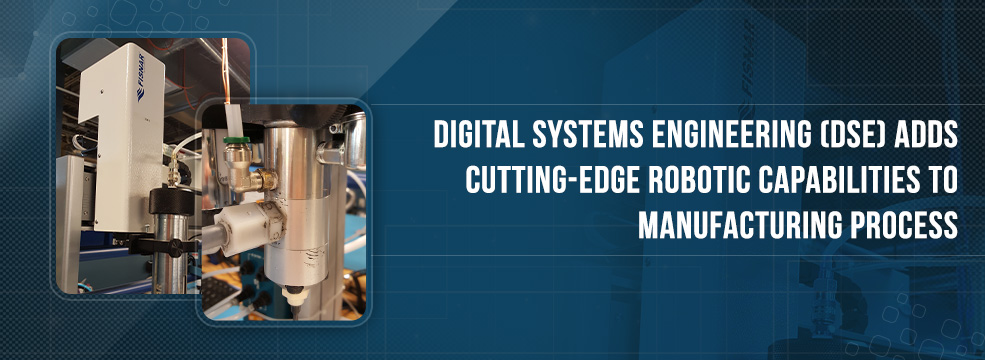

Digital Systems Engineering (DSE) Adds Cutting-Edge Robotic Capabilities to Manufacturing Process

Scottsdale, Arizona – February 2017

DSE is excited to announce the addition of two new robotic gasket dispensing machines to the manufacturing facility. These Fisnar F4000N.1 Series robotic assemblies are used to ensure repeatable sealing techniques for standard off the shelf and custom rugged systems. Specifically, these automated systems assure each and every product shipped from DSE will now have an IP67 seal to prevent the ingress of water, dust, and debris typically found in harsh environments. When compared to legacy techniques, the automated process is easily definable, repeatable (+/- 0.02mm), and more precise with a resolution of 0.001mm. Further, the modular nature of computer-driven programming allows for the process to be scalable for countless products and therefore reduces production lead times and vendor dependency.“Complementing our proven product designs with these mechanized processes has been an exciting effort,” says Erik Copeland, Vice President and Engineering Manager. “Environmental reliability for systems such as rugged displays and mission computers is vital and these assets are instrumental to our commitment to excellence.”

About Digital Systems Engineering

Digital Systems Engineering (DSE) offers custom design, engineering and manufacturing of rugged mobile mil spec and industrial flat-panel LCD displays, advanced video image processing technologies, and rugged computing for multiple markets—primarily the military, security and industrial.DSE is known for it's ability to modify existing COTS products cost effectively to meet stringent specifications and survive rigorous testing. In addition to COTS products, DSE also has a core engineering focus on OEM-driven application specific designs. Since 1995, as a privately held U.S.-owned small business (FAR 19.102), DSE achieved a worldwide reputation for excellence in the design and manufacturing of leading-edge, technology-driven display and computer products—and exceeding customer expectations. Learn more at www.digitalsys.com.

DSE Announces Their Newest Product Launch: The DLX1251 Rugged Touch Screen

The DLX1251 Rugged Touch Screen

Scottsdale, Arizona: Digital Systems Engineering is proud to announce the launch of their newest product, the DLX1251.The industrial rugged touch screen is a drop-in replacement for the widely fielded Planar ® LX1251TI, 997-6192-00LF system. Designed with ruggedness in mind, the DLX1251 withstands exposure to extreme temperatures, shock, vibration, and debris. The DLX screen features a VGA computer input, (2) RS-170 camera inputs, and a resistive touch screen encased in a fully sealed, hard anodized milled aluminum housing. With a high bright LED backlit LCD, the DLX1251 is a perfect solution for all outdoor environments.

Other features include:

- 1″ TFT AM LCD

- 800 Nits Brightness

- XGA (1024 x 768) Resolution

- Commercially Available Connectors

- Various Mounting Options

- IP67/NEMA 6 Sealed Enclosure

- Low Power Consumption

- Anti-Reflective & Anti-Glare Treatments

Digital Systems Engineering’s experience in designing durable electronic systems for demanding military and mining applications was leveraged for this extremely rugged product.About Digital Systems Engineering (DSE): Digital Systems Engineering (DSE) offers custom design, engineering and manufacturing of rugged mobile mil spec and industrial flat-panel LCD displays and computers for multiple markets—primarily the military, security and industrial.Since 1995, as a privately held U.S.-owned small business (FAR 19.102), DSE has achieved a worldwide reputation for excellence in the design and manufacture of leading edge, technology driven display and computer products. Learn more about DSE at www.digitalsys.com