BUILD

Rugged Electronic Manufacturing Capabilities

DSE’s state of the art facility is located in Scottsdale, Arizona, well-positioned in a growing technology hub, encompassing industry giants and emerging enterprises. Our full production floor allows us to develop, assemble and validate products on-site.

VERTICALLY INTEGRATED

From concept to production, DSE streamlines product development to deliver innovation and efficiency.

CONFIGURATION MANAGEMENT

Our integrated system allows for real-time communication between engineering and manufacturing.

QUALITY ASSURANCE

Guided by AS9100, we demonstrate quality throughout each stage of product development.

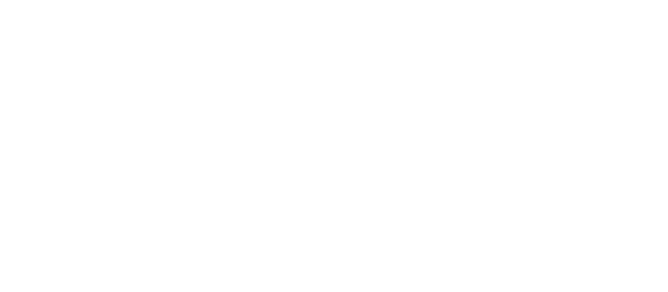

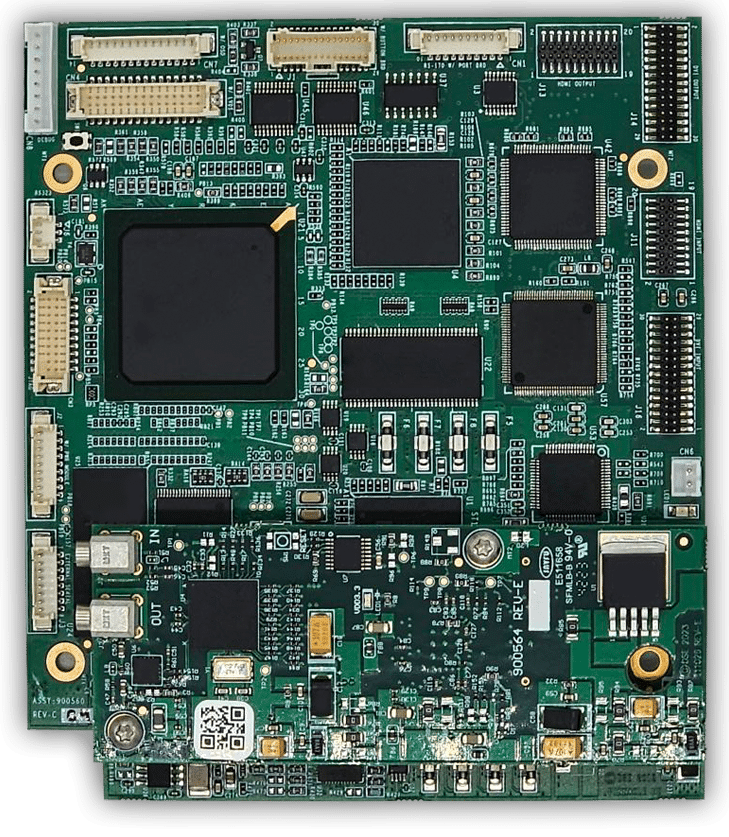

Printed Circuit Board (PCB) Manufacturing

In January 2024, DSE proudly unveiled its printed circuit board (PCB) manufacturing capabilities which allow not only rapid prototyping, circuit validation, and reduced lead times but also the controls, flexibility and efficiency to deliver to customers’ unique specifications.

DSE's in-house PCB manufacturing is made possible by a state-of-the-art surface mount technology (SMT) production line, consisting of:

- Solder paste printer

- Pick and place machine

- Reflow solder oven

- Selective solder machine

- Automated optical inspection (AOI) process

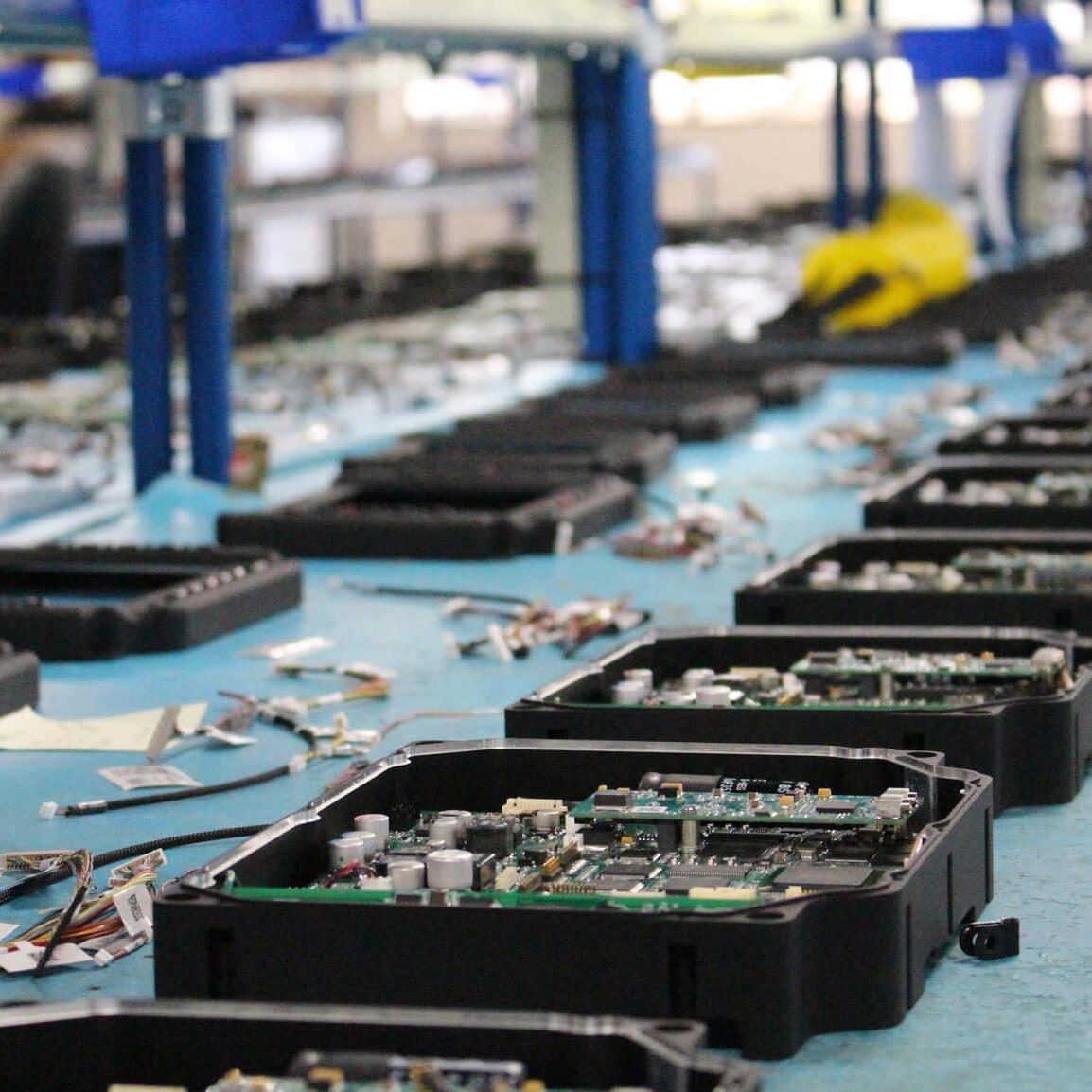

A Vertically Integrated Design-Build Manufacturer

DSE takes pride in a strategic, vertically-integrated approach to designing and manufacturing advanced rugged electronics. By overseeing every stage of product development, from concept to production, DSE is able to streamline the assembly process and ensure each component adheres to design and performance standards as well as customer functional requirements. With in-house capabilities spanning engineering and design, material sourcing, manufacturing and product validation, we have the agility to meet unique program specifications and needs. This comprehensive approach underscores our dedication to delivering innovation, efficiency and quality to our partners.

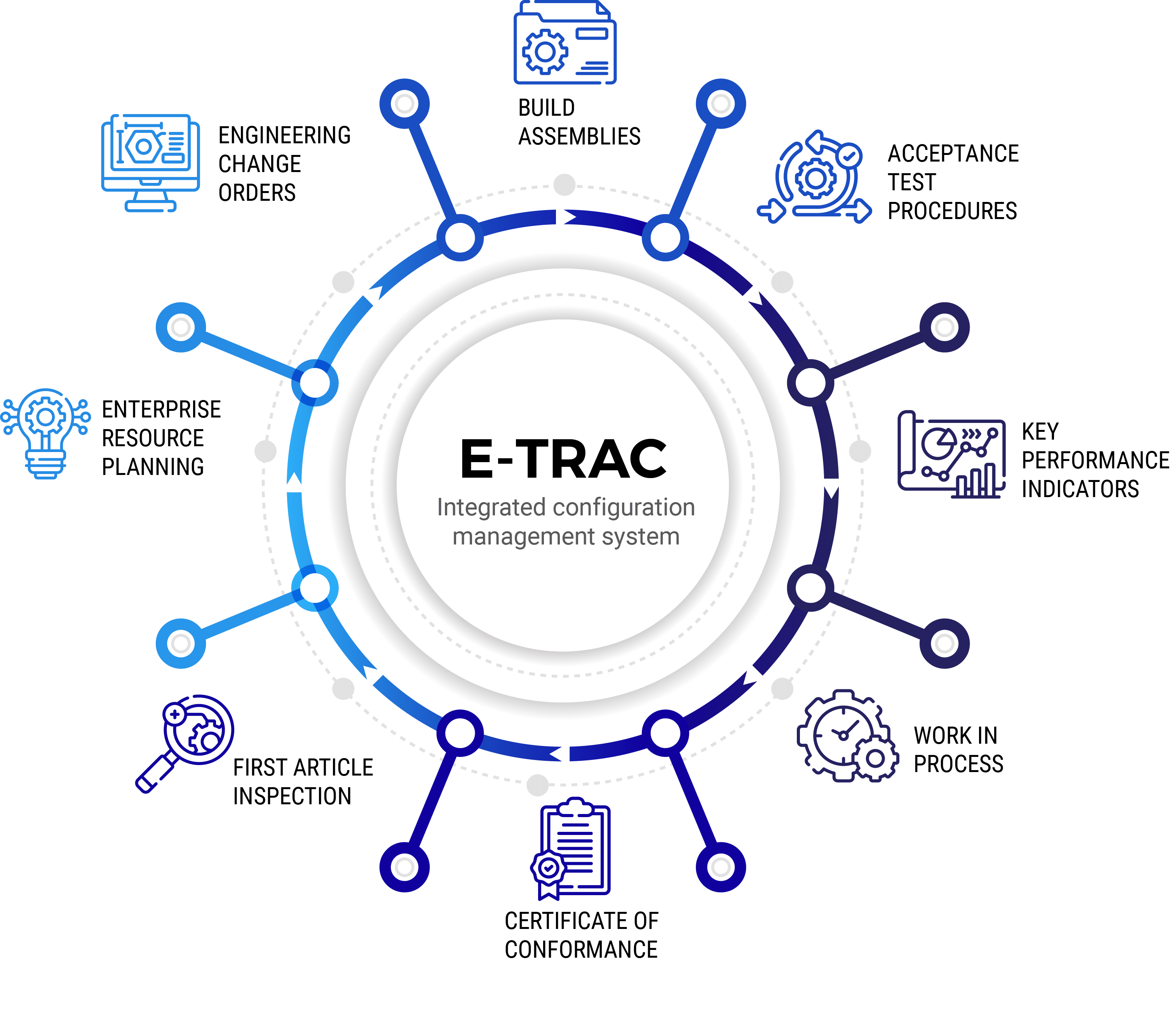

Integrated Configuration Management System

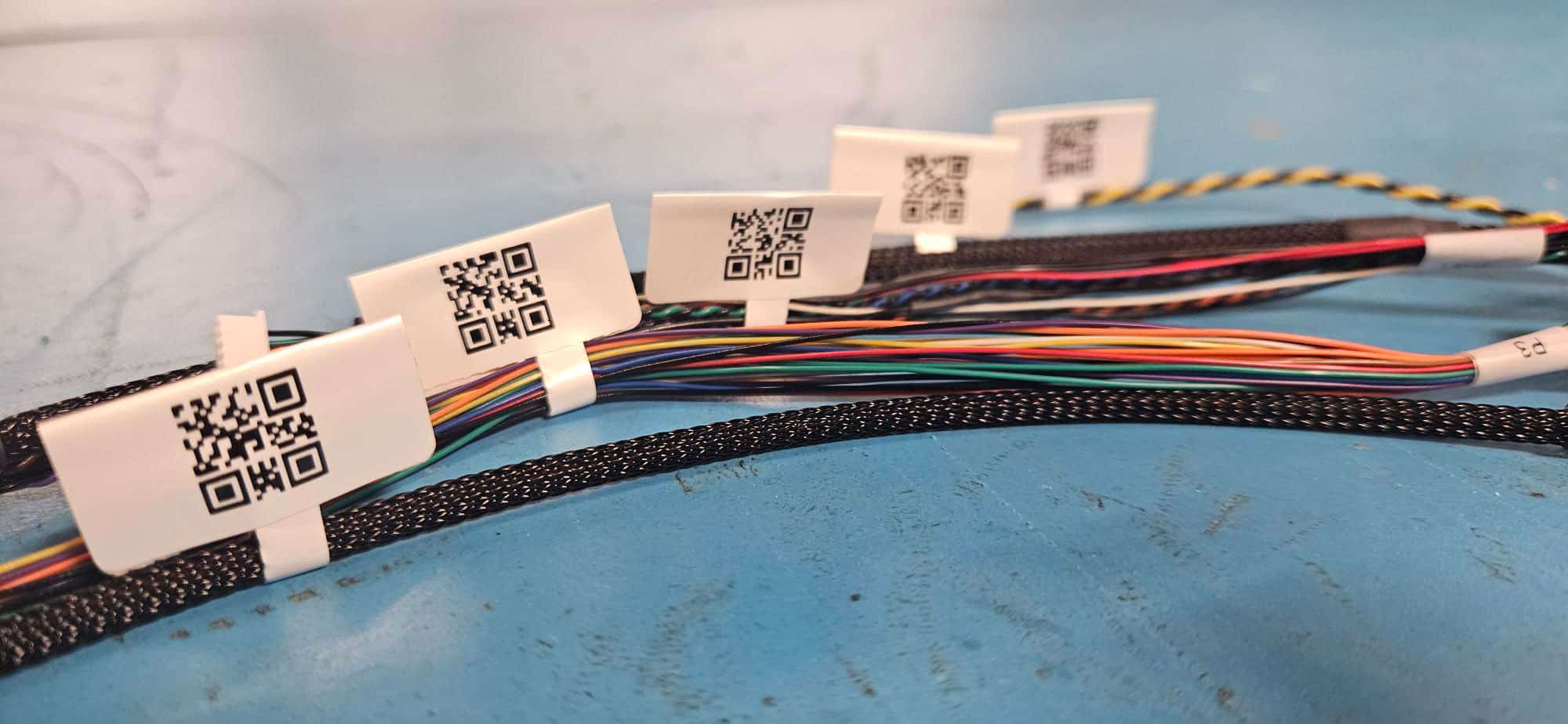

Throughout the assembly process, a technician constructs a detailed “birth certificate” for each product by digitally scanning components as the product is built. The system guarantees that not only is a product built per the most up to date work instructions but also that every component is of the latest revision. This instantaneous exchange of information between the production and engineering teams utilizing ERP, ECO, work instruction, and WIP data, ensures repeatability every time. The end result is a birth certificate for each product containing traceable data to sub-components, supplier lots, manufacturing documentation, and acceptance test results.

E-TRAC, DSE’s integrated configuration management platform allows for seamless connectivity through the product development and manufacturing process in order to deliver unmatched traceability and quality.

Quality at Every Step

Guided by the industry-leading AS9100 Quality Management System, DSE’s approach to building products ensures end-to-end configuration management and repeatable processes drive consistency at every step.

PROCESSES

DSE's utilization of work cell structures enhances the efficiency of our assembly process by reducing the unnecessary movement of products between technicians and workstations. This streamlined approach not only promotes improved product traceability but also facilitates stringent process controls, ultimately leading to the achievement of consistent, high-quality standards.

PEOPLE

Our team of technicians includes experienced professionals with an average tenure of over 15 years at DSE.

PROCEDURES

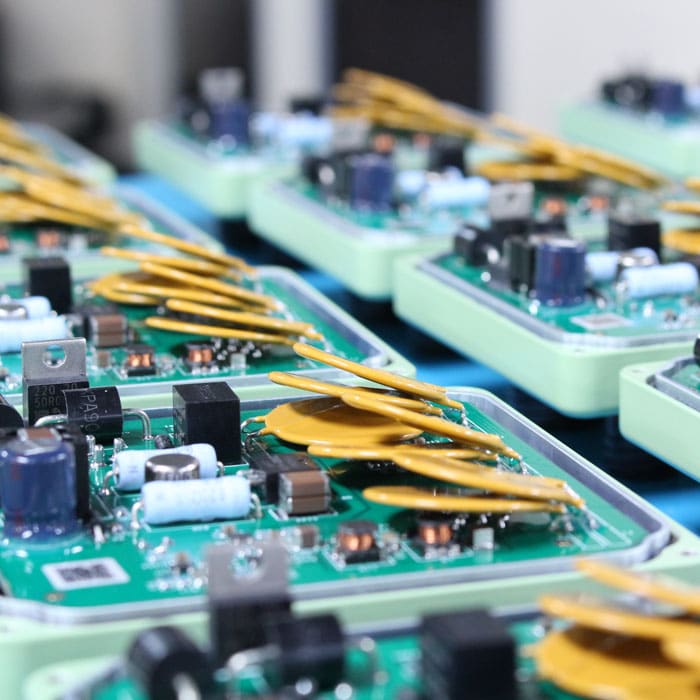

DSE’s meticulous commitment to quality control comprises protocols, such as an Electrostatic Discharge (ESD) mitigation program, and comprehensive in-house product testing. Whether performed as first article validation or on a continual basis, our in-house environmental stress screenings ensure the consistent production of reliable, high-performance products.

In-house ESS capabilities include:

- High Temperature

- Low Temperature

- 3-Axis random vibration with simultaneous thermal cycling

- Submersion

- Boot Impact

- Power surge

- High-pressure spray

- Burn-in

- Wrench Impact

- Reverse polarity

- Sharp Impact

- Power drop out

- Simultaneous temperature and vibration