Rugged Electronics for Food and Beverage

Whether on a seed planter in Iowa, in a Californian packaging facility, or above a high-temperature grill in a restaurant kitchen, DSE products have their place within all of these important steps of the Food & Beverage industry. The products must survive continual 24/7 operation, steam cleaning wash downs, and the rigors of everyday use. Learn more about the DSE products helping the food service industry below.

View all Food and Beverage products

US-Owned, US-Built, US-Controlled

The DSE design and production teams are located right here in America and with hundreds of years of engineering experience, no task is too tall. Our AS9100 Quality Management System is the organizational framework that demands excellence in engineering, product validation, production, and traceability.

MIL-Spec Quality

With a background in developing MIL-Spec electronics for allied forces around the world, DSE designs its products to meet the most rigid environmental requirements. It is not uncommon for our electronic devices to have a mean time between failure (MTBF) of greater than 40,000 operational hours. If our electronics can survive on the battlefield, they’ll hold up in your application.

MIL-Spec Quality

With a background in developing MIL-Spec electronics for allied forces around the world, DSE designs its products to meet the most rigid environmental requirements. It is not uncommon for our electronic devices to have a mean time between failure (MTBF) of greater than 40,000 operational hours. If our electronics can survive on the battlefield, they’ll hold up in your application.

User Input

Displays, computers, and network controllers must provide users with real-time information to do their jobs but equally important, they shall allow users to input data. Touch screens rated for a million actuations, programmable bezel keys, GPIO, and configurable application software are all tools to collect operational data from the manufacturing floor.

Advanced Sealing Techniques

To survive the conditions and environments typically found in the agriculture or food and beverage industries, devices must be designed to prohibit the ingress of water, dust and other foreign debris. Come "Behind the Build" with DSE as we explore the sealing techniques that ensure our rugged electronics can meet the most extreme demands.

Food and Beverage Products

AWM

All Weather Monitor

- VGA and RS-170 video inputs

- IP67 sealed enclosure

- Touch screen options

- Wide range DC input

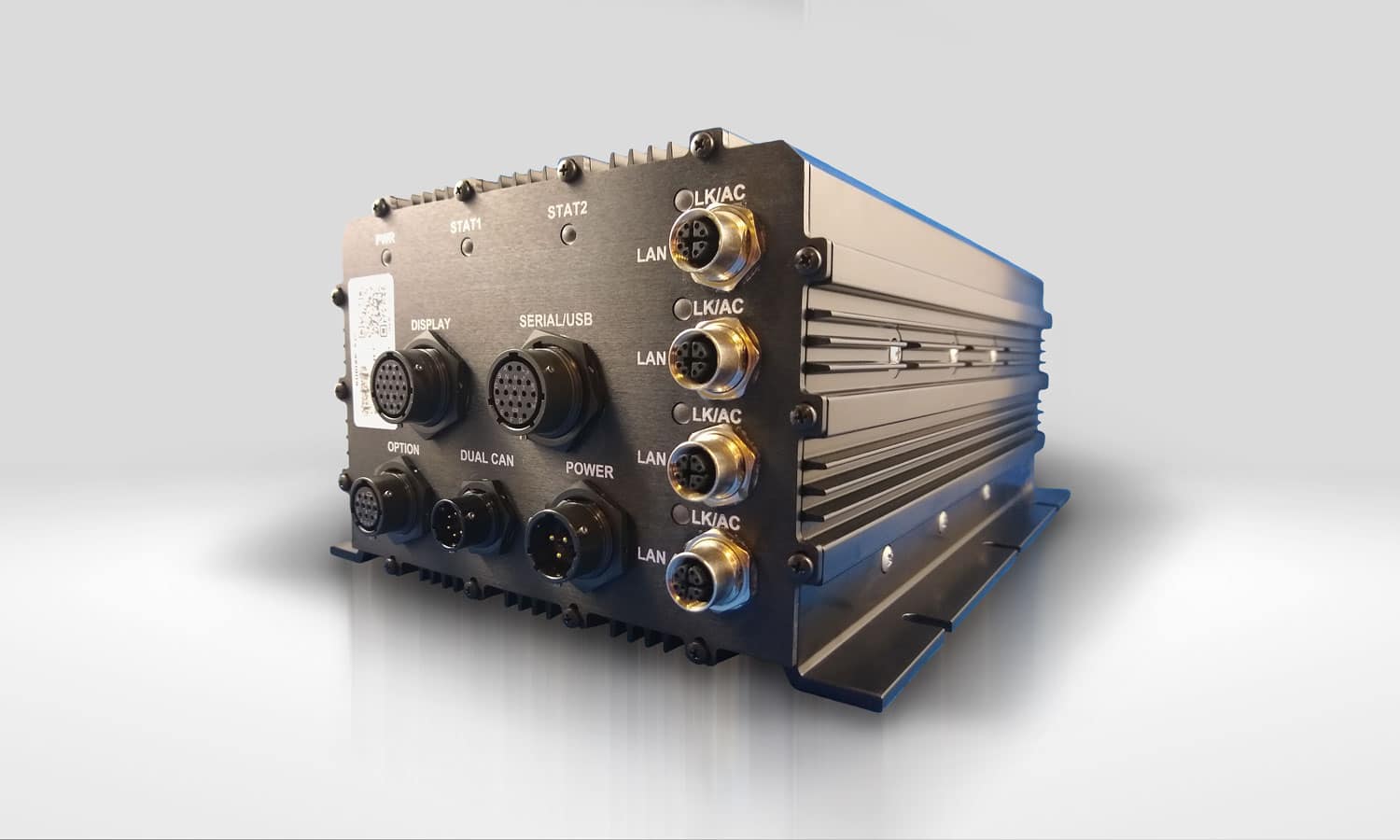

ALPHA

Rugged Mission Computer

- Fully sealed computer system

- Intel, Atom and ARM processors

- GPS, cellular, Gigabit Ethernet, dual CANBus, WiFi interfaces

- Battery backup protection

DLX

Industrial Rugged Touch Screen

- VGA video input

- Resistive hardened touch screen

- Integrated speaker

- Wide range DC input

MC-10

COM Express Type 10 Computer

- (2) Gigabit Ethernet interface

- Removable mSATA drive

- I/O expansion slots

ISD

Industrial Smart Display

- Embedded Celeron® processor

- Resistive or capacitive touch screen

- Ethernet interface

WorkForce

HD Video and USB Hub

- 1280 x 768 high-def resolution

- (2) DVI-I inputs (DVI-D and/or DVI-A)

- (5) integrated USB hub ports

VS8

Gigabit Ethernet Switch

- (8) Gigabit Ethernet ports, RS-232 and Power

- MIPS CPU with DDR-2 Memory

- DMA-based Frame Extraction, Performance Monitoring, Ethernet OAM

Industrial Controllers

Industrial Touch Screen Controllers

- High Definition LCD’s

- Capacitive Touch Screens

- Gigabit Ethernet Interface, POE

VH3

Video Distribution Hub

- (3) Composite Video (NTSC/PAL) Inputs

- (6) Composite Video (NTSC/PAL) Outputs, (2) per Input

- 28 VDC Power Input

VH4

Rugged HD-SDI Video Switch

- SD-SDI, HD-SDI and 3G video processing

- Dual CANBus (J1939), RS-422 & USB interfaces

- PIP, POP, Quad Viewing

From the DSE Knowledge Center:

Behind the Build: Advanced Sealing Techniques to Protect Rugged Electronics

To survive the rugged environments typically found in the aerospace and defense, oil and gas, mining and agriculture…

Behind the Build: Hard Anodized Aluminum

Join DSE as we take you ‘Behind the Build’ to learn more about the processes that go into designing and building rugged…

From Specification to Production: Developing Custom Solutions

Over the course of 25 years, Digital Systems Engineering has refined the process of designing and building custom…

3 Factors to look for in a Rugged Electronics Manufacturer

With a variety of COTS and OEM solution manufacturers in the market, choosing suitable rugged electronics for your…